Delivering a clean energy retrofit: 800mm SAE 1 bellhousing for 250kW electric motor

Todayjbj Techniques has developed a bespoke solution for a customer replacing a diesel engine with a 250kW, D355 frame electric motor on heavy equipment. Critical to this retrofit was the ability to interface the new motor with the existing SAE1/SAE14over-centre clutch, preserving the option to revert to diesel if required.

Smarter detection, easier configuration

TodaySensoPart has released a powerful new software update for its proven VISOR sensor series. Available free of charge, the update introduces major functionality upgrades, including automatic geometric shape detection, precise circle measurement, and a new browser-based configuration interface.

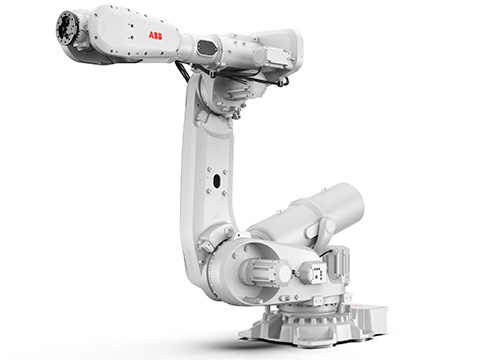

ABB expands large industrial robot portfolio

TodayABB Robotics is expanding its large robot portfolio with the launch of the IRB 6730S, IRB 6750S and IRB 6760. The introduction of these new robots, alongside the wider portfolio of next generation robots launched since 2022, now means the company can offer a lineup of 11 next generation robot families comprising 60 variants.

Two new roughing pumps for analytical applications

TodayLeybold has launched two new versions of its oil-sealed rotary vane pumps for analytical applications. The new developments are characterised by their high pumping speed, low noise level and maintenance intervals of up to 24,000 hours in LC or GC MS applications (Liquid or Gas Chromatography-Mass Spectrometry).

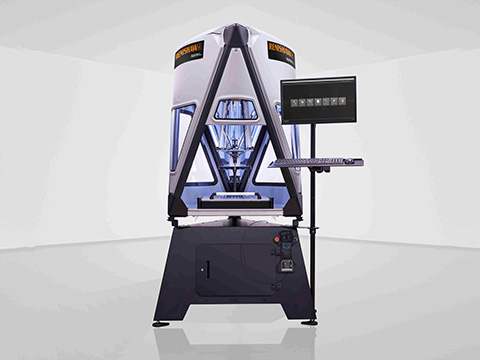

Renishaw introduces dual-method gauging system

TodayRenishaw has announced the launch of its latest solution for shop floor process control, the Equator-X 500 dual-method system. This enables manufacturers to select the optimum inspection method, Absolute or Compare, for their process challenge, effectively deploying two systems in one.

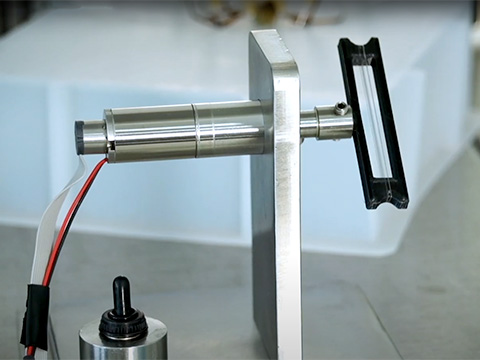

Multi-axis motion control drives pipe-based robots

1 day agoSurveying and maintaining underground pipes can be complex and resource intensive. To streamline the process, construction and facility management teams are increasingly turning to robots that can provide inspection as well as repair. To propel these robots and drive their tools, all within a space-constrained environment, compact and reliable multi-axis motion systems are essential. maxon engineer, Tamas Hertelendi, explains.

Seeing Machines and Mitsubishi Electric enter Guardian collaboration

1 day agoSeeing Machines, the advanced computer vision technology company that designs AI-powered operator monitoring systems to improve transport safety, announces that it has entered a Referral Agreement with Mitsubishi Electric Europe to enable greater driver safety across the region.

ABB unifies motor and drive in a streamlined plug-and-play platform

1 day agoABB's new LV Titanium Variable Speed Motor platform delivers the benefits of a high-efficiency motor and variable speed drive (VSD) technology in a single, compact, customisable, plug-and-play solution that enables industrial customers to minimise their energy consumption, save money and reduce carbon emissions.

Integrated motor in miniature NEMA 8 frame size

1 day agoApplied Motion Products (AMP) has expanded its TSM StepSERVO integrated motor line with a brand new, truly miniature, NEMA 8 frame model - the USA based motion control leader's smallest all-in-one closed loop servo motor, drive and controller combination.

Easy-to-use and cost-effective DIN-rail power supply range

12 days agoThe PIANO product family from PULS has been designed for customers who need reliable, easy-to-use and cost-effective DIN rail power supplies. PULS PIANO power supplies are a future-proof and cost-effective investment for systems integrators, these basic power supplies will permanently reduce system costs.

EAO provides high-performance HMI solutions for food and beverage machinery

18 days agoEAO offers advanced HMI solutions designed specifically for the food and beverage manufacturing industry. EAO's broad range of HMI components and systems enables precise, efficient operation and monitoring of automated packaging lines while ensuring maximum safety and reliability.

Industrial Technology Magazine - Spring 2025

Cover Story

2 Selecting the optimal end-of-arm equipment

Industrial update

8 Harness AI to transform development and engineering

10 Recyclable artificial vision system could be sweet for the environment

12 £83bn boost to UK economy if SMEs achieve their growth ambitions

14 Li-ion raw materials impact the battery recycling market

Aerospace report

16 Specialised aircraft bearings for extreme heat and pressure

Food manufacturing

18 Grasping the full potential of sensors

19 Baking rolls on a large scale

Medical report

20 Advanced drive systems could revolutionise surgical robots

21 Miniature ballscrews for medical applications

Design Engineering

23 Discovering the benefits of a machined spring

24 Thread grooves with the highest requirements

26 Bonding artificial turf to various substrates

28 Take action if you’re suffering from arc eye

Machine building

31 Flat packed kits versus fully assembled solutions

32 Encoders for position and motion control

34 Programming barrier to the democratise of automation

36 Keeping conveyors rolling

38 Overcoming the reluctance to automate with robotics

40 Ultrasonic inspection machine relies on servo drive system

42 Harmonised standards for risk assessments

44 Safe, seamless collaboration between cobots and humans

46 Control upgrade reduces configuration time by 75%

48 Machine vision improves component inspection